Precision Mechanical Airflow Control System

-

Role: Mechanical Design Engineer

-

Scope: Designing and prototyping a mechanical airflow control system for offset smokers

-

Focus: End-to-end development, CAD, FEA, CFD, torque calculations, GD&T, and prototyping

Last Updated: January 2026

Define

User Observation:

I met Brian, an avid barbecue cook who regularly uses an offset smoker. I noticed that he adjusts the firebox intake entirely by feel and visual estimation, with no reliable way to know actual airflow or return to prior settings.

Problem Statement:

Without precise, repeatable airflow control:

-

Temperature swings occur, forcing constant monitoring

-

Trial-and-error adjustments waste time and fuel

-

Maintaining consistent cooking results is difficult

Insight:

Serious cooks lack a reliable, repeatable method to understand and manage airflow into their smokers.

Market Context:

-

Offset smokers are used by millions of BBQ enthusiasts; ~80% of US homeowners own a grill or smoker.

-

High-frequency vent adjustments (every 30–60 minutes) require constant attention and intuition, creating a tangible pain point for precision cooking.

Goal

North Star:

How might we enable serious barbecue cooks to manage airflow in offset smokers with greater precision and repeatability, without removing the hands-on nature of fire management?

Success Criteria:

-

Fine-grained airflow control (< 10% of intake area) with repeatable settings

-

One-handed, intuitive operation with tactile feedback

-

Robust performance under high temperatures, smoke, and particulate exposure

-

Simple to install and maintain with minimal moving parts

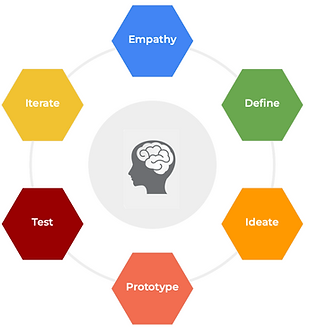

Approach

Empathize

-

Observed and interviewed serious offset smoker users.

-

Documented pain points: frequent vent adjustments, difficulty returning to prior settings, and reliance on visual or tactile cues.

-

Identified key user needs: visibility, repeatability, and intuitive control of airflow.

Define

-

Established engineering requirements covering:

-

Functional: airflow modulation, repeatability, manual control

-

User interaction: intuitive mapping, tactile feedback, one-handed operation

-

Performance: adjustment resolution, thermal stability, long-term accuracy

-

Environmental & durability: ash/smoke tolerance, corrosion resistance, thermal expansion

-

Integration: retrofit capability, ease of mounting

-

Validation: bench and field testing, user repeatability

-

-

Clarified non-goals: system does not automatically control temperature, optimize fuel efficiency, or eliminate user decision-making.

Ideate

Airflow Mechanism Concepts

Evaluated four potential vent mechanisms using hand calculations and airflow modeling:

Insights:

-

Circular aperture: slightly higher airflow (+3%) but very complex to fabricate and seal.

-

Vertical slider: ~97% of maximum airflow, mechanically simpler, easier to seal, robust → chosen as primary architecture.

Human-Machine Interface Concepts

To determine how the user would actuate the airflow mechanism, several input methods were evaluated. Each concept was scored (1–5) on intuitiveness, precision, usability, feedback, durability, aesthetics, and mechanical complexity, reflecting how human behavior informs mechanical design.

Insights:

-

Crank handle and throttle lever scored highest, balancing intuitiveness, precision, and feedback.

-

Decision: Start prototyping with the crank handle due to ease of iteration, precise tactile feedback, and forgiving assembly tolerances. Throttle lever reserved for potential future testing.

Prototype

Design Architecture:

-

Vertical slider vent actuated via crank handle converting rotational input to linear vent motion.

-

Indexed detents provide ~5% step resolution.

-

Weatherstrip seals prevent air leaks; components designed to withstand high heat, ash, and smoke exposure.

-

Estimated moving parts: 5–10 for simplicity, durability, and field serviceability.

Next Steps:

-

Build a functional crank-slider prototype to validate ergonomics and mechanical performance.

-

Bench-test airflow vs. adjustment input to confirm resolution and repeatability.

-

Prepare for initial field testing with experienced users to evaluate usability and robustness.

Impact (So Far)

-

Demonstrates human-centered mechanical design by linking observed user behaviors to a physical solution.

-

Illustrates quantitative trade-offs in airflow performance vs. mechanical complexity.

-

Highlights structured design thinking: empathize → define → ideate → prototype.

-

Lays a foundation for iterative testing and refinement based on real-world use, with a clear path toward field-validated performance.

Last Updated: January 2026