Forensic Failure Analysis Structural Turnbuckle

-

Role: Mechanical Engineer

-

Scope: Led forensic failure analysis on a legacy turnbuckle with no specs

-

Focus: SEM/EDS analysis, hypothesis-driven testing, fatigue and stress evaluation

Define

A residential porch deck experienced a sudden structural failure when a load-bearing turnbuckle fractured after approximately 18 years of service.

The component had been operating under sustained tensile load in an outdoor environment, and its failure posed immediate safety and liability risks.

Critical constraints:

-

No original design drawings, material specifications, or maintenance records

-

Long-term static loading with environmental exposure

-

Unclear failure mechanism at the time of fracture

The homeowners requested a forensic engineering investigation to determine the cause of failure and provide guidance to prevent recurrence.

Goal

Determine the root cause and failure mechanism of the fractured turnbuckle and translate findings into actionable, fatigue-resistant design guidance, despite severe uncertainty and missing historical data.

Approach

Failure Framing Under Uncertainty

With no design documentation available, the investigation began by framing all plausible failure mechanisms and identifying the physical evidence required to confirm or rule out each.

Hypothesized mechanisms:

-

Stress corrosion cracking

-

Tensile overload

-

Manufacturing or material defects

-

Fatigue crack initiation and propagation

Each hypothesis was mapped to expected fracture features, material signatures, and loading behaviors.

Experimental & Analytical Investigation

Fracture Characterization

-

Conducted visual and optical microscopy to document fracture morphology and macroscopic features

-

Used Scanning Electron Microscopy (SEM) to locate crack initiation sites and distinguish brittle vs. ductile fracture behavior

Material Verification

-

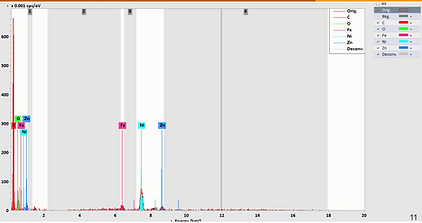

Applied Energy-Dispersive X-ray Spectroscopy (EDS) to identify alloy composition and assess material suitability for long-term structural loading

Fatigue Evaluation

-

Performed fatigue analysis to correlate crack growth behavior with long-term cyclic and sustained loading conditions

-

Quantified crack propagation consistent with multi-year service exposure

Hypothesis Testing & Iteration

-

Compared observed fracture features against known failure mode benchmarks

-

Systematically ruled out stress corrosion, overload, and manufacturing defects

-

Refined analysis as evidence converged on a single dominant mechanism

The investigation iterated between experimental evidence and mechanical analysis until all observations aligned.

Impact

-

Primary failure mechanism: Long-term fatigue crack propagation culminating in sudden fracture

-

Contributing factors:

-

Zinc–aluminum alloy with limited fatigue resistance

-

Sustained tensile loading over an extended service life

-

Lack of inspection and fatigue-aware design margins

-

-

The fracture initiated at a localized stress concentration and propagated incrementally over years before catastrophic failure.

-

Delivered evidence-based guidance to reduce future risk:

-

Recommend alternative materials with improved fatigue performance

-

Increase design safety margins for long-term static and cyclic loading

-

Implement inspection intervals for load-bearing tension hardware

-

Avoid material selections optimized for cost or corrosion resistance at the expense of fatigue life

-

-

These findings directly informed safer structural design and maintenance decisions for similar applications.