60-Day Innovation Sprint: Rapid Integration of Gas Emissions Technology

Define

After acquiring Scientific Aviation, ChampionX faced a dual challenge:

-

Protect critical market share in emissions and water management

-

Meet aggressive methane regulations with field-ready solutions

Scientific Aviation’s airborne and drone-based methane detection systems were advanced but not ruggedized for harsh, ground-level deployment. Normally, adapting these technologies would take 6–18 months, but leadership demanded solutions in 60 days under intense pressure from competitors, customers, and regulators.

Current State: Field-Ready Methane Detection & Water Management

-

Existing technology was highly accurate but fragile and airborne-focused

-

Ground deployment required ruggedization, integration, and workflow adaptation

-

Cross-functional teams needed actionable concepts fast to inform executive decision-making

Goal

Support rapid exploration of technical pathways in three urgent domains:

-

Methane leak detection

-

Gas remediation

-

Produced water optimization

Mission: Deliver actionable, development-ready concepts fast enough for executive review while compressing a traditional multi-month development process into a 60-day sprint.

Approach

Empathize

-

Engaged with cross-functional engineering, chemical, and operations teams

-

Identified environmental, operational, and system-level constraints

-

Mapped real-world challenges including vibration, thermal cycling, dust, and high-pressure production flows

Define Core Engineering Problem

Rapidly translate advanced, airborne-grade sensing and chemical technologies into robust, ground-ready, and operationally feasible solutions under extreme time constraints.

Investigation Goals / Design Requirements

-

Generate multiple solution pathways for each technical domain

-

Evaluate feasibility against environmental, operational, and regulatory constraints

-

Integrate concepts into coherent, actionable systems that leadership could greenlight

-

Compress 6–18 months of development into a 60-day cycle

Ideate / Hypothesis Generation

-

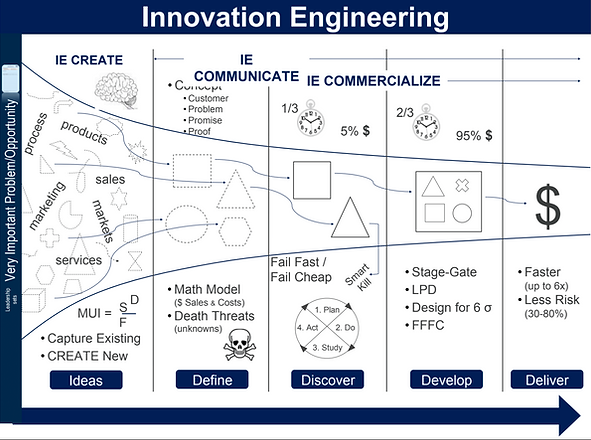

Applied Innovation Engineering framework for rapid, structured problem-solving

-

Generated multiple solution approaches with a “fail-fast, fail-cheap” mindset

-

Balanced creativity with practical engineering constraints and systems-level thinking

Methane Leak Detection (EmissionsIQ)

-

Conceptualized ground-adapted sensor platforms with passive site scanning

-

Proposed integration of edge-computing telemetry for real-time monitoring

Gas Remediation (Sealing Agent)

-

Designed concepts for injectable sealants operating under full production flow

-

Evaluated material approaches and system-level deployment strategies

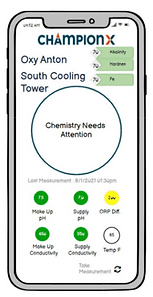

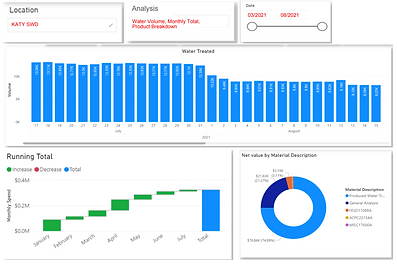

Produced Water Optimization (Digital Water Advisor + Simplicity)

-

Developed ideas for modular sensor fusion systems

-

Proposed predictive AI dashboards and actionable operational KPIs

Impact

-

$55M+ projected revenue potential validated across platforms

-

Established internal innovation framework reducing risk 30–80% and compressing time-to-market up to 6x

-

Leadership greenlit multiple concepts for development after 60 days

-

Earned Blue Belt Certification in Innovation Engineering

Key Takeaways

-

Demonstrates ability to translate complex, uncertain challenges into structured engineering solutions

-

Shows skill in mechanical reasoning, systems thinking, and disciplined creativity under extreme time pressure

-

Highlights capacity to compress months of development into weeks while delivering high-impact, actionable concepts

-

Emphasizes cross-disciplinary collaboration to achieve measurable business and technical outcomes

This project reflects my approach to engineering: think systemically, iterate rapidly, and deliver high-impact, operationally viable solutions under extreme constraints.